BigLever’s unmatched expertise in helping organizations achieve Product Line Engineering (PLE) success has enabled us to create a robust, repeatable path to organizational transformation: onePLE™.

With onePLE, we provide a single deliverable to your organization — a successful, fully-operational Feature-based PLE Factory.

The name onePLE comes from the idea that we provide one all-inclusive packaged solution — everything you need to create, standup and successfully operate your Feature-based PLE Factory with highly trained and skilled PLE executives, managers, technical leaders, and practitioners. onePLE is available for organizations of any scale: an entire enterprise, a division, a business unit, or an organization responsible for the production of a single product line.

BigLever’s onePLE package includes:

- Licenses for BigLever Gears and Bridge Integrations for all PLE practitioners.

- Expert mentoring of PLE managers and technical leaders on designing, creating, transitioning, and operating your PLE factory.

- Organizational change guidance based on the industry’s most successful organizational change strategies.

- World-class expertise and guidance for solving your hardest PLE organizational and technical challenges.

- A comprehensive PLE Body of Knowledge including process descriptions and training materials for every aspect of Feature-based PLE.

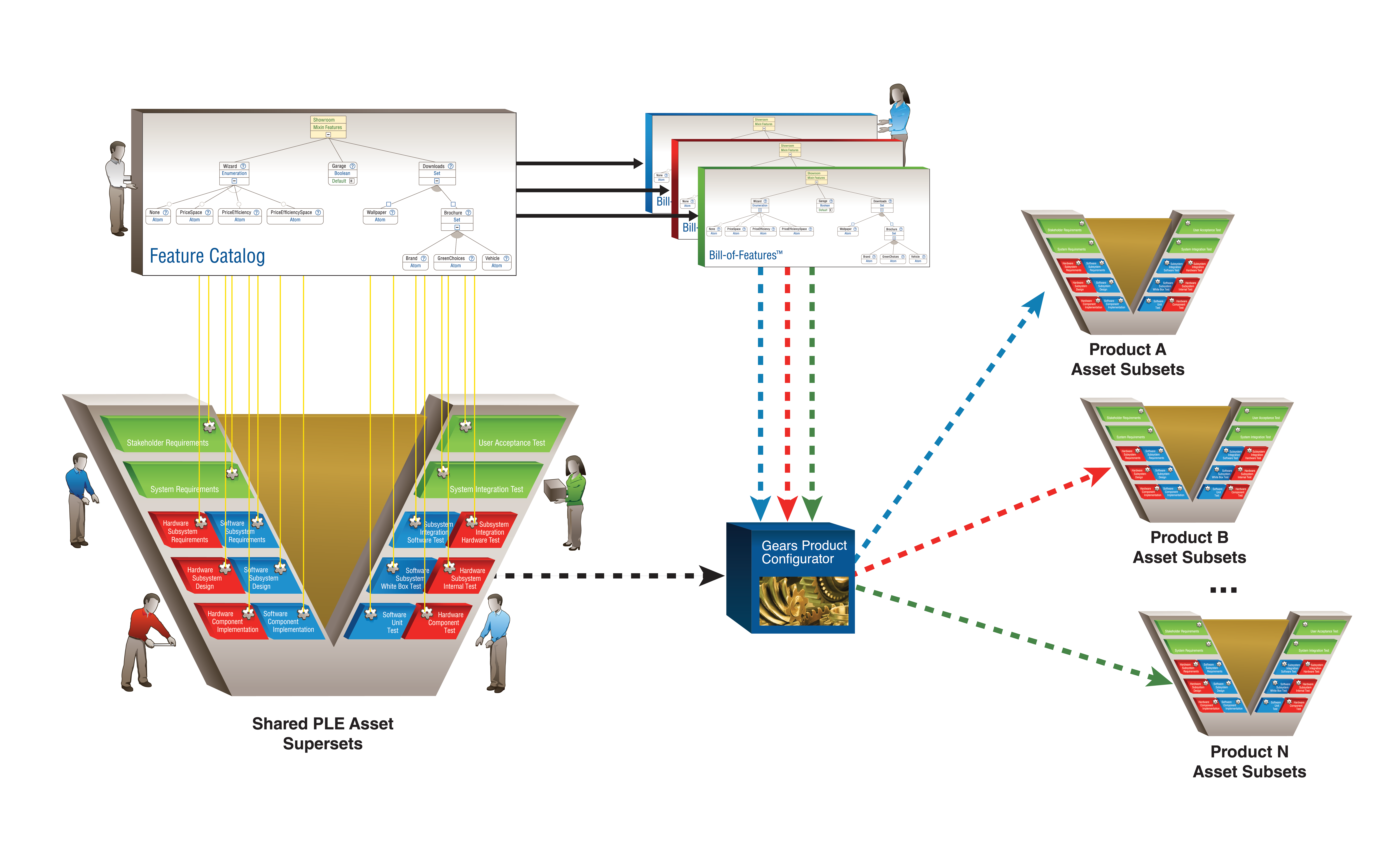

The Feature-based PLE Factory.

onePLE delivers your PLE capability based on the factory concept that underpins BigLever’s industry-leading approach to successful PLE:

- The Asset Supersets (bottom left) are the shared digital assets for a product line, and no asset is duplicated.

- The Feature Catalog (top left) contains all the feature options available for all the products in that product line.

- Bill of Features (top right) specifies a product in terms of its features.

- The Product Configurator (blue box) automatically produces product-specific instantiations of the shared assets.

BigLever’s Gears PLE Lifecycle Framework provides the technology foundation for onePLE and your PLE Factory.

Your organization’s PLE journey — with onePLE.

Transitioning to PLE means moving your organization to the PLE Factory paradigm for the creation, production, and evolution of the products in your portfolio. BigLever assists you in building, staffing and operating your PLE factory. As part of onePLE, we also help you establish a PLE Center of Excellence which provides invaluable support for your organization’s PLE journey, and accelerates your transition across the enterprise.

PLE Living Business Plan.

A living business plan for PLE is foundational for adoption success. onePLE includes the creation of your living business plan, which encompasses:

- Multi-Level Scope: How broadly will PLE be applied across the enterprise? What products will be brought under the PLE umbrella?

- Guiding Coalition: Who is the core group of champions guiding the PLE transition?

- Importance and Urgency: Why PLE? Why now? Establishing urgency is the #1 ingredient for organizational change.

- Vision and Strategy: What will the organization be like under PLE? How will we get there? PLE must be part of a business strategy, and supported by a PLE vision, owned by executive leadership.

- Communication Plan: How will the PLE vision be shared with the organization at large?

- Funding and Funding Plan: How will the up-front costs be managed?

- Roadblocks and Risks to a successful adoption, with mitigation strategies.

PLE Concept of Operations.

The PLE Concept of Operations is the “operating manual” for your PLE Factory on a day-to-day basis. PLE processes and policies are documented in the ConOps, which defines roles, responsibilities and procedures for your PLE activities. A ConOps can apply at the enterprise or business unit level, or to individual product line groups.

PLE Body of Knowledge.

BigLever’s unmatched expertise in PLE has allowed us to create an industry first — a comprehensive body of PLE knowledge, which powers your PLE Center of Excellence. The PLE Body of Knowledge contains detailed process descriptions for every aspect of Feature-based PLE, including all of the activities involved in establishing and operating your PLE Factory:

- producing your Living Business Plan and Spiral Adoption Plan,

- establishing and managing the PLE Factory,

- establishing the organizational structure for the Factory,

- building a Feature Catalog and Bills-of-Features for your product line,

- engineering shared asset supersets with variation points and traceability,

- using the Factory to build and deliver products,

- managing change and product line temporal evolution,

- ensuring IP protection, and operating in a classified environment,

- funding policies for the PLE Factory,

- defining PLE metrics and measures, and much more.

Anyone in your organization can go to the Body of Knowledge, look up their role, determine its definition and the processes and activities for which they are responsible, and then undertake associated training. Training materials include an inventory of specialized courses, best practices compendia, Quick Reference Guides, slide presentations, detailed how-to videos, white papers, and more.

PLE and Organizational Change — Your Path to PLE.

While the PLE Factory plays a central role in the PLE story, it is only one part of a larger picture. Unlike other technical disciplines, PLE cannot be applied by individuals alone, but must be embraced by whole teams, projects, and organizations. PLE cannot be achieved with tooling alone, but must be part of a business strategy sponsored by executive leadership. Just as these things are true of actual manufacturing factories, they are true for your PLE Factory.

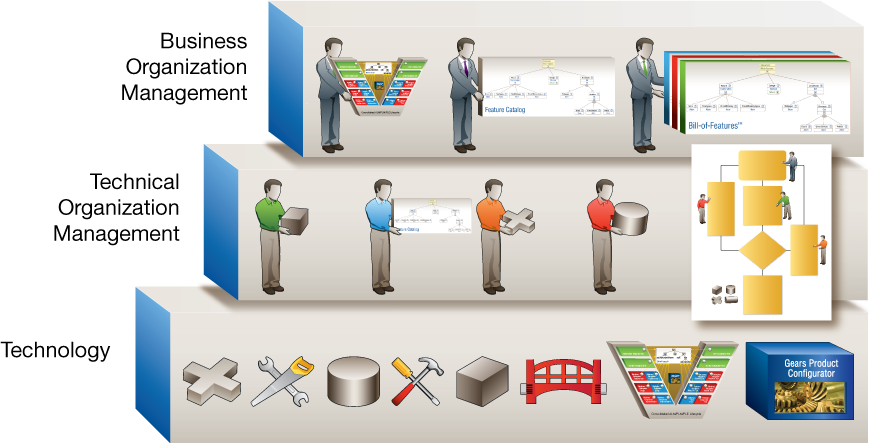

BigLever’s 3-Tiered PLE Methodology illustrates the three concerns that must be addressed for successfully transitioning your organization, and establishing your PLE Factory:

Business Organization Management: Focuses on the people, roles, and processes that utilize the PLE Factory to achieve the business objectives of the enterprise, as well as provide the necessary leadership support for the PLE Factory during its operation.

Technical Organization Management: Focuses on the people, roles, and processes that operate the PLE factory.

Technology: Puts in place and maintains the tool and technology environment to operate the PLE Factory.

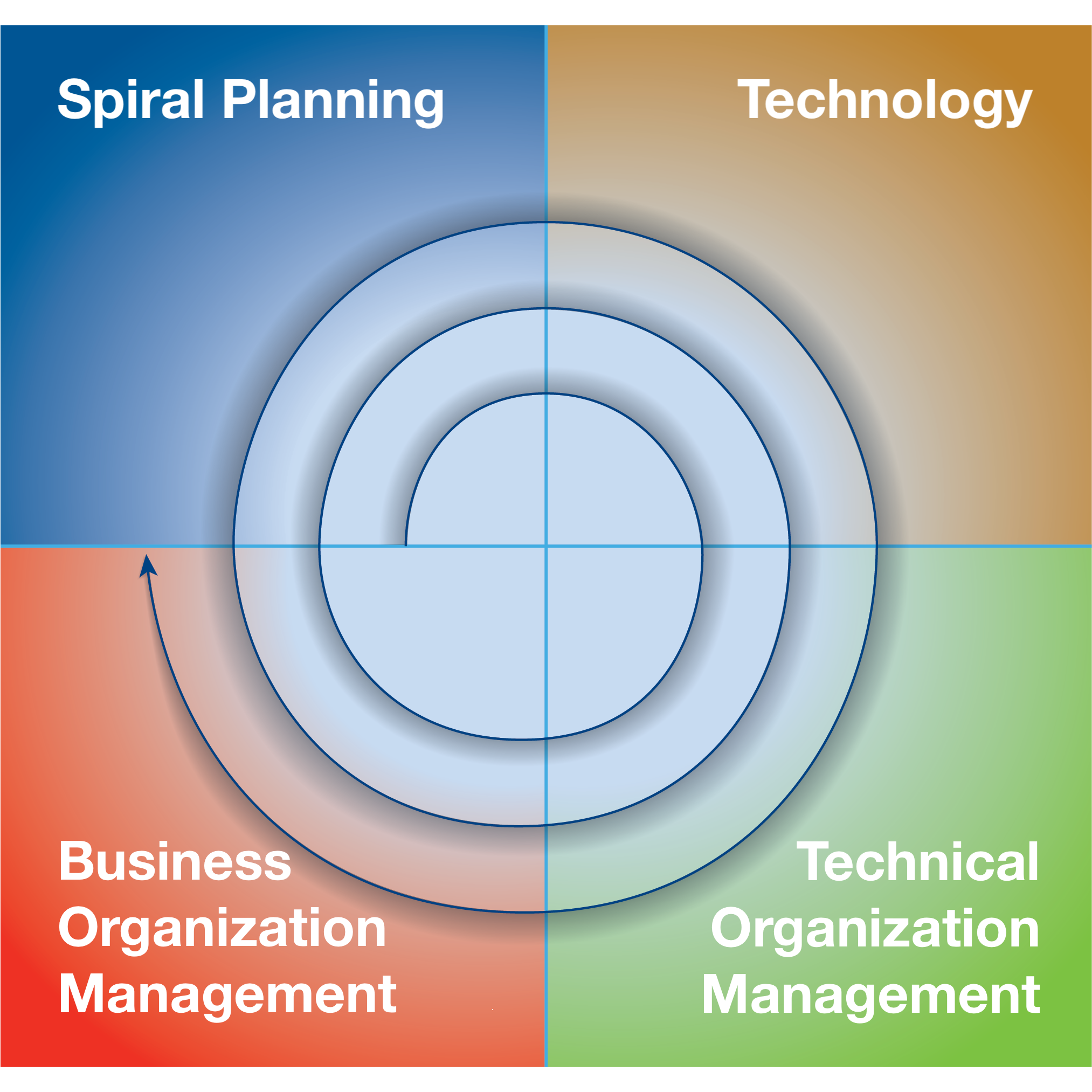

PLE Spiral Adoption Plan.

Your transition to PLE will not happen in one massive shift. BigLever’s approach to PLE transition, provided through onePLE, is highly incremental. Your organization can take the journey to PLE in small steps that can be absorbed without disrupting ongoing production.

Nevertheless, each step brings benefit and leaves you better off than before, and closer to the goal of full PLE capability. To facilitate incremental transition planning, we employ a spiral model of PLE adoption. Spiral models chart an incremental path through various areas of activity.

With the completion of each cycle, your organization is further along its adoption journey (as measured by the distance from the origin point at the center). Progress is steady, but no cycle overwhelms your ability to absorb new practices and processes.

Getting Started with onePLE.

The foundation of BigLever’s onePLE approach is our Getting Started process — which centers on a pair of hands-on working events:

- Technical Getting Started Workshop

- Business Getting Started Workshop

These two workshops constitute your organization’s first step for establishing your full PLE capability — the PLE Factory.